Construction at Your Site: Essential Tips for EHS Managers. Years ago, I found myself in a situation I never anticipated. I had just accepted an EHS Manager role for a company preparing to launch a new manufacturing plant. The hiring process was grueling, with multiple interviews, assignments, and tests. I was eager to dive into the operational aspects of the position, ensuring safety and compliance in a startup. However, on my first day, I learned something critical: the plant I was hired to manage didn’t exist yet. It had yet to be built. Suddenly, I was no longer just an EHS Manager. I was the site owner’s representative for a major construction project.

This was a world I wasn’t prepared for. Construction was nothing like managing safety within a fully operational facility. New risks, unfamiliar laws, and constant coordination with contractors became my daily challenges. It was overwhelming at first, but it taught me lessons that I carry with me to this day. If you, too, find yourself navigating the complex world of construction projects, this article will guide you through the essential responsibilities and strategies for success.

As a representative of the site owner, you carry a significant responsibility for safety and compliance. OSHA standards, state-specific laws, and industry best practices provide the foundation for your role. At the most basic level, site owners must eliminate known hazards, such as unstable structures, hazardous materials, or exposed wiring. Additionally, contractors must be informed of any potential risks on-site. Adherence to OSHA regulations is non-negotiable, as these rules are designed to prevent accidents and ensure safe working conditions.

When site owners actively manage construction, they must supervise compliance with safety norms. This includes verifying the use of Personal Protective Equipment (PPE) and ensuring adherence to protocols for tasks like working at height, electrical safety, and material handling. Non-compliance can lead to severe legal and financial consequences.

State laws add complexity. For instance, New York’s Labor Law § 240, known as the Scaffold Law, requires fall protection for workers at height. Labor Law § 241(6) mandates compliance with industrial safety codes. These laws make it clear: failure to meet your obligations as a site owner can result in liability for injuries or accidents.

The importance of proactive risk management becomes clear when you consider legal cases like Ross v. Curtis-Palmer Hydro-Electric Co. In this case, a worker was injured due to faulty scaffolding, and the court held the site owner liable under Labor Law § 240. Similarly, in Rizzuto v. L.A. Wenger Contracting Co., unsafe site conditions led to a worker’s injury. The court ruled that the owner had a duty to address known hazards and enforce safety standards. In Haimes v. New York Telephone Co., a worker’s injury due to infrastructure risks highlighted the importance of communicating potential dangers to contractors.

These cases serve as cautionary tales. They show how oversight or mismanagement can lead to serious consequences for both workers and site owners.

To navigate the complexities of construction projects, an EHS manager must adopt a proactive and structured approach. This begins long before the first brick is laid.

Start with Contractor Selection

Selecting the right contractors is the foundation of a safe and successful project. Your process should prioritize safety performance as a key evaluation metric. Metrics such as past injury records, employee training, and PPE provision should carry significant weight. To formalize this, develop a contractor management procedure that defines how the EHS team is notified of contractor selections and ensures that safety criteria are non-negotiable.

You can include in your quantitative method system other criteria such as prior positive or negative experiences with the contractor, recommendation letters, or third-party endorsements.

For those interested in applying a quantitative method to contractor selection, at the end of this article is an example of a weighted scoring system.

Additional Evaluation Criteria

Another effective method to evaluate compliance is conducting audits at sites where the contractor is currently working. Create a detailed checklist of questions, which can later be reused for your own site evaluations. Each response can be scored or assigned a compliance percentage, with the average score determining the contractor’s suitability. This method offers a realistic view of the contractor’s practices, but may require significant resources, such as travel to distant project sites. For EHS managers with limited construction experience, outsourcing audits to specialized firms is recommended.

Agreement on EHS Standards

The most critical element of contractor management is ensuring contractors agree to your company’s safety standards. In one audit I conducted, the company required all bidding participants to submit a signed letter acknowledging their understanding of the EHS requirements. This letter, signed by the contractor’s leadership, confirmed their financial and technical ability to meet these standards. No contractor was allowed to participate in the bidding without this acknowledgment.

Many companies mistakenly believe that including safety requirements in contracts is sufficient. It is not. Contractors base their cost estimates on standard practices. If your company’s safety expectations significantly exceed these standards, the contractor might either refuse to sign the contract or, worse, sign it without the intention to comply. This leads to conflicts or compromises during the project.

Contractual Requirements

Once a contractor is selected, it is crucial to include EHS requirements in the contract. A standard approach is to create pre-made standard forms within the contractor management procedure. These can include general safety requirements, as well as specific guidelines for cleaning, cafeteria services, repair teams, transportation services, and scaffolding installation.

Every contract should include the following provisions:

- Contractors may only hire subcontractors with the site owner’s consent, ensuring the same safety standards apply.

- All incidents, including accidents, property damage, or traffic collisions, must be reported within a certain time frame.

- Penalties for non-compliance should be clearly defined.

However, penalty systems need careful consideration. Excessive fines can deter good contractors, while bad contractors may dispute or refuse to pay penalties altogether. If you suspend work instead of issuing fines, delays may become costly, and management might pressure you to compromise. A proven alternative is a warning system similar to American football or soccer penalties: minor infractions result in a 10 yard or a yellow card, and serious or repeated violations lead to being benched or a red card, barring the contractor’s worker from site access. Contractors are incentivized to ensure their key personnel comply, minimizing disruptions.

Being prepared for large-scale contractor engagement starts long before the first bid is submitted. As an EHS manager, it is crucial to establish clear procedures and systems now to ensure a seamless process when the time comes. Start by drafting detailed contractor management procedures, outlining responsibilities, evaluation criteria, and safety expectations. These procedures must be aligned with both regulatory standards and your company’s operational goals.

Collaboration with your legal team is essential. Work closely with them to review and refine these procedures, ensuring compliance with local, state, and federal regulations. Legal approval will also strengthen your ability to enforce contractor agreements and manage disputes effectively.

Equally important is preparing your procurement team. Conduct regular training sessions to familiarize them with EHS requirements and ensure they understand the critical role safety metrics play in contractor selection. A well-informed procurement team will be your strongest ally in upholding safety and compliance standards during the bidding process.

By taking these steps today, you position your organization for success when contractor engagement ramps up. Proactive planning not only minimizes risks but also establishes a culture of accountability and excellence. Together, let’s build a safer and more efficient future—one procedure, one partnership, and one project at a time.

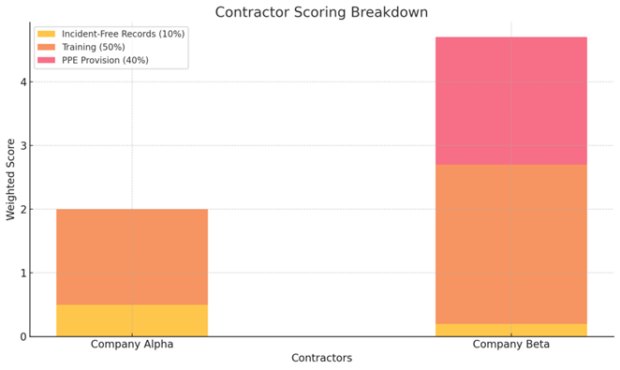

Appendix: Contractor Scoring Calculations

Scenario: Comparing Two Contractors

Company A:

- No incidents in the past five years.

- Trained employees for working at height but lacks first-aid training records.

- Does not provide Personal Protective Equipment (PPE).

Company B:

- Three incidents in the past three years.

- Fully trained workers for all relevant tasks.

- Provides comprehensive PPE.

Assigned Weights to Evaluation Criteria

- Incident-Free Records: 10%

- Training: 50%

- PPE Provision: 40%

Scoring Calculation

Company A:

- Incident-Free Record = 5×0.1=0.55 \times 0.1 = 0.55×0.1=0.5

- Training = 3×0.5=1.53 \times 0.5 = 1.53×0.5=1.5

- PPE Provision = 0×0.4=00 \times 0.4 = 00×0.4=0

- Total Score = 0.5+1.5+0=2.00.5 + 1.5 + 0 = 2.00.5+1.5+0=2.0

Company B:

- Incident-Free Record = 2×0.1=0.22 \times 0.1 = 0.22×0.1=0.2

- Training = 5×0.5=2.55 \times 0.5 = 2.55×0.5=2.5

- PPE Provision = 5×0.4=2.05 \times 0.4 = 2.05×0.4=2.0

- Total Score = 0.2+2.5+2.0=4.70.2 + 2.5 + 2.0 = 4.70.2+2.5+2.0=4.7

Result

Company B achieves a higher total score (4.7) compared to Company A (2.0.) Company B meets the minimum passing threshold (3.0.) Based on these results, Company B is the preferred contractor.

References

https://www.nycourts.gov/reporter/archives/ross_curtis-palmer.htm?utm_source

https://casetext.com/case/rizzuto-v-la-wenger-contracting-co-inc?utm_source

https://casetext.com/case/haimes-v-new-york-tel-co?utm_source

This article was written by Olga. Olga Bodiagina is an experienced Environmental, Health, and Safety (EHS) professional with 18+ years in manufacturing, construction, and food production. I have led safety and environmental initiatives at KBR, Otis Elevator Co., and Saint-Gobain and hold a Master’s degree in Forestry, along with certifications in Occupational Safety and ISO standards.