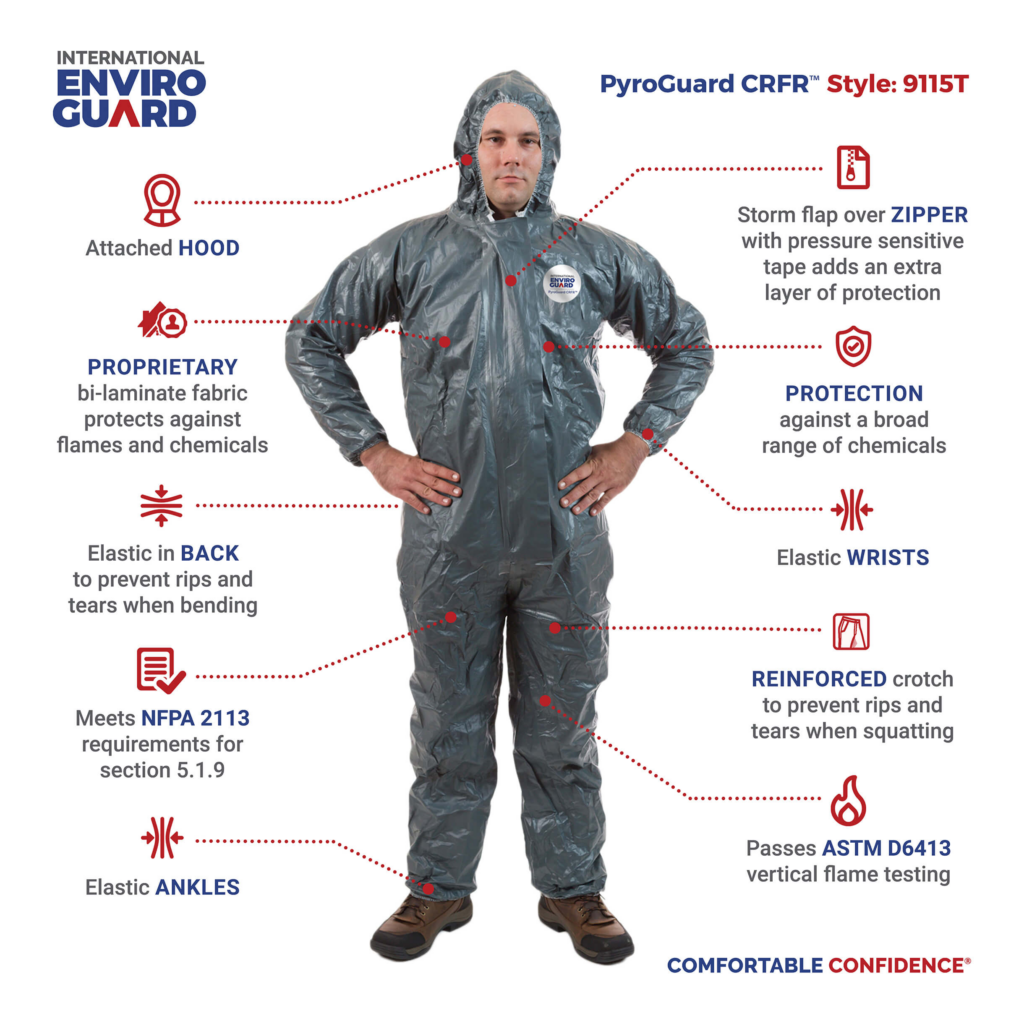

Fire-Resistant and Chemical-Resistant Clothing: Protecting Workers from Extreme Hazards, OHS Magazine . In industries where employees are exposed to extreme hazards like fire, chemicals, and heat, the right protective clothing can mean the difference between life and death. Fire-resistant (FR) and chemical-resistant (CR) clothing are essential components of personal protective equipment (PPE) in many high-risk work environments. Whether in construction, firefighting, oil and gas, or chemical manufacturing, these specialized garments protect workers from burns, chemical burns, and other serious injuries.

This article delves into the importance, design, and regulatory standards for fire-resistant and chemical-resistant clothing and provides best practices for employers to ensure their workforce is adequately protected.

Understanding Fire-Resistant Clothing

Fire-resistant (FR) clothing is designed to self-extinguish when exposed to flame, reducing the risk of burns and giving the wearer crucial time to escape the danger zone. This type of clothing is commonly used in environments where workers may come into contact with open flames, electrical arcs, or hot surfaces. Key industries requiring FR clothing include firefighting, oil and gas, electrical utilities, and welding.

How Does Fire-Resistant Clothing Work?

FR clothing works by using special fabrics or treating materials that are inherently resistant to fire. These materials prevent flames from spreading and reduce the heat transfer to the skin. There are two main categories of FR fabrics:

- Inherent FR fabrics: These are materials, like Nomex or Kevlar, that are naturally flame-resistant. Their fire-resistant properties are built into the fibers, making them long-lasting and reliable.

- Treated FR fabrics: These materials, such as cotton, are chemically treated to resist ignition. While effective, the treatment can wear off over time, meaning regular inspection and replacement may be necessary.

FR clothing also minimizes the risk of molten material sticking to the fabric, further reducing the severity of burns in high-heat environments.

Key Features of Fire-Resistant Clothing

When selecting FR clothing for your workforce, several features should be considered:

- Heat and Flame Resistance: The clothing should provide a high level of protection against both radiant and direct heat.

- Durability: Fire-resistant clothing must withstand harsh conditions without degrading quickly.

- Comfort and Breathability: Workers need to be able to perform their tasks comfortably, even in extreme conditions. Lightweight, breathable fabrics can improve compliance.

- Arc Flash Protection: In electrical environments, FR clothing often includes protection against arc flashes, a type of electrical explosion that can be fatal.

Chemical-Resistant Clothing: Guarding Against Toxic Substances

Chemical-resistant (CR) clothing is vital for workers who handle hazardous chemicals, whether in liquid, gas, or particulate form. Exposure to toxic chemicals can cause burns, respiratory problems, and long-term health effects, making CR clothing a key element of workplace safety in sectors like chemical processing, agriculture, and industrial cleaning.

How Does Chemical-Resistant Clothing Work?

CR clothing creates a barrier between the worker and harmful chemicals, preventing skin contact and minimizing inhalation exposure. This clothing is typically made from materials such as polyvinyl chloride (PVC), rubber, neoprene, or polyethylene, which provide excellent protection against various chemicals.

Different materials offer resistance to specific chemicals, so it’s essential to select the right material based on the type of hazard present. For example:

- PVC is effective against acids and alkalis.

- Neoprene is resistant to oils, greases, and certain chemicals.

- Tyvek and polyethylene suits are commonly used for protection against fine particles and light chemical splashes.

Key Features of Chemical-Resistant Clothing

When choosing CR clothing, employers should ensure that it meets the following criteria:

- Chemical Compatibility: The material must be resistant to the specific chemicals workers may encounter.

- Liquid and Vapor Protection: In addition to splash resistance, some environments require protection from vapor or gas exposure.

- Seam Sealing: To ensure full protection, seams and closures must be well-sealed to prevent any chemical penetration.

- Fit and Coverage: CR clothing should cover the worker fully, including gloves, boots, and hoods where necessary, to provide complete protection.

Regulatory Standards and Compliance

Both fire-resistant and chemical-resistant clothing must meet stringent regulatory standards to ensure their effectiveness. Employers are responsible for providing PPE that complies with these regulations to safeguard their workers adequately.

Fire-Resistant Clothing Standards

In the U.S., FR clothing must comply with the National Fire Protection Association (NFPA) standards:

- NFPA 2112: This standard outlines the minimum requirements for FR garments in environments where flash fires may occur.

- NFPA 70E: This standard focuses on protecting workers from electrical arc flash hazards, ensuring FR clothing provides adequate protection against electrical burns.

Other global standards include:

- EN ISO 11612: A European standard for FR clothing used in environments with heat and flame risks.

- CAN/CGSB 155.20: A Canadian standard for flash fire protection.

Chemical-Resistant Clothing Standards

CR clothing must meet standards like:

- OSHA 1910.120 (Hazardous Waste Operations and Emergency Response): This regulation specifies requirements for chemical protective clothing during hazardous waste handling.

- EN 14605: A European standard specifying requirements for liquid-tight protective clothing.

Best Practices for Employers

Providing fire-resistant and chemical-resistant clothing is only the first step in protecting workers. Employers must also ensure that the clothing is used correctly and maintained properly. Here are some best practices:

1. Hazard Assessment

Conduct a thorough hazard assessment to identify the specific risks workers face. This assessment will guide the selection of appropriate FR or CR clothing based on exposure to fire, chemicals, or other hazardous materials.

2. Proper Fit and Comfort

Ill-fitting protective clothing can reduce mobility, leading to non-compliance or accidents. Ensure that garments are available in various sizes and tailored to different tasks, allowing workers to move freely while still being protected.

3. Training and Education

Workers should be trained on the correct use, care, and maintenance of FR and CR clothing. This includes understanding the limits of the protective gear, recognizing signs of wear and tear, and knowing when to replace the clothing.

4. Maintenance and Inspection

Regular inspections are crucial to ensure the integrity of the protective clothing. For FR clothing, check for fading or damage to the fire-resistant properties, especially in treated fabrics. For CR clothing, inspect for tears, punctures, or degradation of the chemical barrier.

5. Layering for Enhanced Protection

In some environments, workers may need both fire and chemical resistance. Layering FR clothing with CR outer layers can offer comprehensive protection against multiple hazards. It’s essential to ensure that the garments are compatible and do not hinder each other’s effectiveness.

Conclusion

Fire-resistant and chemical-resistant clothing are indispensable tools in protecting workers from the most dangerous hazards they may encounter. As industries evolve and safety standards continue to advance, the development of new materials and designs is making protective clothing more effective and comfortable than ever before.

Employers who prioritize investing in high-quality FR and CR clothing not only comply with safety regulations but also protect their most valuable assets—their employees. By conducting proper hazard assessments, providing training, and enforcing regular inspections, companies can create a safer working environment and minimize the risks of injury from fire and chemical exposure.

McRey, OHS Magazine Editor