Industrial hygiene and exposure control are essential elements of Occupational Health and Safety (OHS), focusing on identifying, controlling, and monitoring workplace hazards to protect worker health. For students studying industrial hygiene, understanding the principles and methods used to minimize exposure to harmful substances is crucial, as these practices are fundamental to creating safe working environments across various industries. This article will cover the basics of industrial hygiene, exposure control strategies, and the key skills and knowledge areas that will benefit students entering this field.

1. What is Industrial Hygiene?

Industrial hygiene is a field within OHS dedicated to anticipating, recognizing, evaluating, and controlling environmental hazards that may affect worker health. This includes physical, chemical, biological, and ergonomic hazards present in the workplace. Industrial hygienists work to identify these hazards and recommend strategies to mitigate or eliminate worker exposure.

2. Key Components of Industrial Hygiene

There are four main steps in industrial hygiene:

- Anticipation: Proactively identifying potential hazards based on workplace conditions and practices.

- Recognition: Observing and assessing the presence of hazards through inspections and hazard identification processes.

- Evaluation: Measuring and analyzing exposure levels through monitoring and testing to determine if they exceed acceptable limits.

- Control: Implementing measures to reduce or eliminate exposure to these hazards.

These steps form the backbone of industrial hygiene, and each step is crucial for ensuring a safe and healthy work environment.

3. Hazard Identification in the Workplace

Hazard identification is the first step in managing exposure risks. Hazards in industrial environments vary but often include:

- Chemical Hazards: Substances like solvents, heavy metals, pesticides, and other chemicals that can cause health issues through inhalation, skin contact, or ingestion.

- Biological Hazards: Bacteria, viruses, fungi, and other biological agents that may cause infections, particularly in healthcare and laboratory environments.

- Physical Hazards: Noise, radiation, and temperature extremes that can impact hearing, vision, and overall health.

- Ergonomic Hazards: Repetitive movements, poor posture, and equipment that can lead to musculoskeletal disorders.

Identifying these hazards typically involves routine inspections, observations, and reviewing Material Safety Data Sheets (MSDS) for chemicals.

4. Exposure Limits and Monitoring

Exposure limits are regulatory guidelines indicating the maximum allowable exposure level for various hazards. The most commonly used limits are:

- Permissible Exposure Limits (PELs) set by OSHA.

- Threshold Limit Values (TLVs) recommended by the American Conference of Governmental Industrial Hygienists (ACGIH).

- Recommended Exposure Limits (RELs) from the National Institute for Occupational Safety and Health (NIOSH).

Monitoring workplace environments to ensure compliance with these limits is critical. This can involve:

- Air Sampling: Measuring airborne contaminants to determine if they exceed PELs.

- Noise Monitoring: Measuring decibel levels to prevent hearing loss.

- Biological Sampling: Testing for pathogens or other biological agents.

Regular monitoring is essential for determining whether existing control measures are effective or if additional actions are needed.

5. Control Strategies in Industrial Hygiene

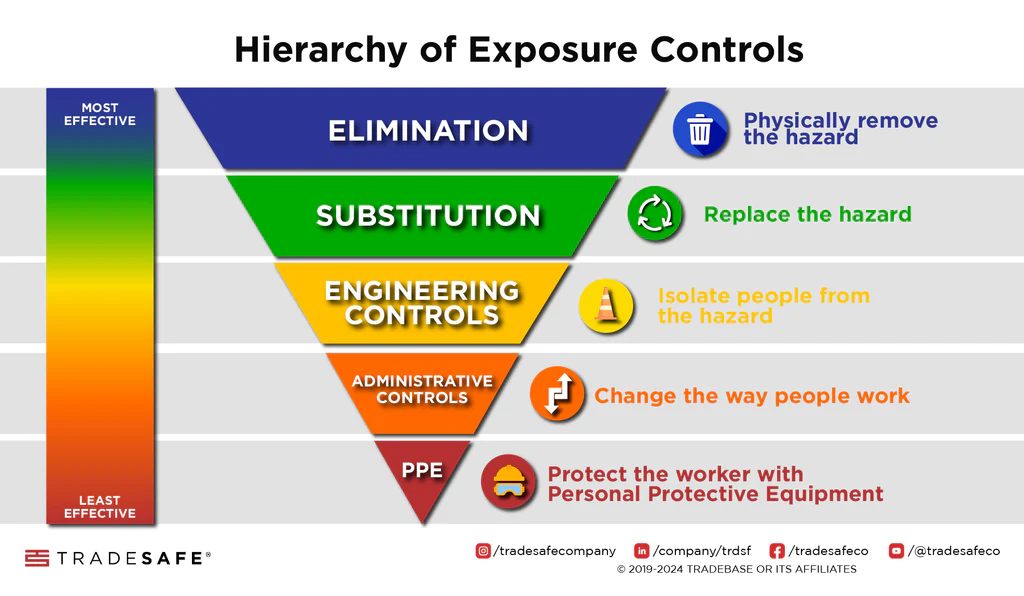

Control strategies are methods used to reduce or eliminate exposure to identified hazards. The Hierarchy of Controls is a framework widely used in industrial hygiene, listed from most effective to least effective:

- Elimination: Physically removing the hazard. For example, replacing a hazardous chemical with a safer alternative.

- Substitution: Replacing a hazardous substance or process with a less dangerous one.

- Engineering Controls: Isolating people from the hazard. Examples include ventilation systems to reduce airborne contaminants and noise barriers to limit exposure to high decibel levels.

- Administrative Controls: Changing work practices or policies to reduce exposure, such as rotating workers to reduce their time in high-risk areas.

- Personal Protective Equipment (PPE): Providing workers with protective gear, such as respirators, gloves, and goggles, as a last line of defense.

These control methods are often used in combination to provide comprehensive protection.

6. Skills for Future Industrial Hygienists

To succeed in industrial hygiene, students should focus on developing a blend of technical, analytical, and interpersonal skills, including:

- Analytical Skills: Ability to evaluate data from exposure monitoring and risk assessments.

- Technical Knowledge: Familiarity with industrial hygiene equipment and technology, including air sampling devices, noise meters, and software used for data analysis.

- Communication Skills: Ability to explain complex safety concepts to workers and management clearly and effectively.

- Attention to Detail: Recognizing subtle risks and ensuring accurate data collection and analysis.

- Regulatory Knowledge: Understanding OSHA regulations and international standards like ISO 45001 for effective compliance.

7. Career Opportunities in Industrial Hygiene

Industrial hygiene offers a wide range of career opportunities. Industrial hygienists work in manufacturing, healthcare, government agencies, consulting firms, and educational institutions. Potential career paths include:

- Safety Specialist: Focusing on workplace health, safety, and environmental compliance.

- Environmental Health Specialist: Overseeing environmental hazards in the workplace and implementing protective measures.

- Compliance Officer: Ensuring workplaces adhere to regulatory standards and safety protocols.

- Consultant: Providing expertise on industrial hygiene to various industries.

These roles allow industrial hygienists to apply their skills in diverse settings, with a focus on improving workplace safety and protecting worker health.

8. Emerging Trends in Industrial Hygiene

As the field evolves, several emerging trends are shaping industrial hygiene practices, including:

- Wearable Technology: Devices that monitor exposure levels in real-time, providing instant feedback on environmental hazards.

- Data Analytics and AI: Using data analysis to predict potential hazards and assess risk factors more accurately.

- Sustainability and Green Chemistry: Emphasis on environmentally friendly practices and materials to reduce workplace hazards.

Staying informed about these trends will be valuable for students as they prepare for careers in industrial hygiene.

Conclusion

Industrial hygiene and exposure control play a critical role in protecting workers from workplace hazards. For students in OHS, understanding hazard identification, exposure limits, and control strategies is fundamental to building a successful career in this field. By mastering these skills and staying current with industry trends, future industrial hygienists can contribute significantly to creating safer, healthier work environments across various industries.